Every Renovation Dollar Matters: Your Easy Step-by-Step Guide

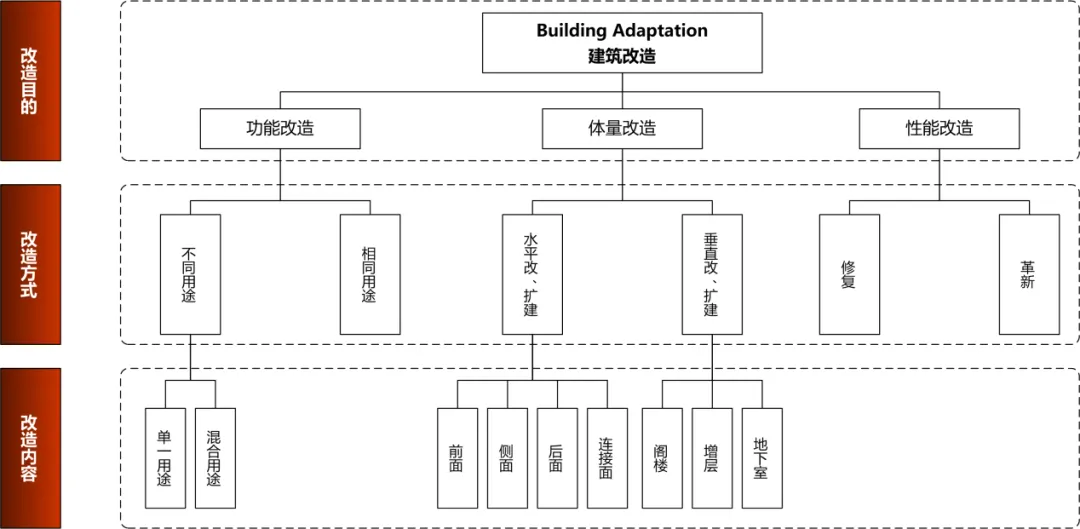

Hospitals around the world share a common challenge: aging buildings that must be renovated to remain safe, efficient, and patient-centered. But without careful planning, renovations can disrupt care, raise infection risks, and inflate costs. At Nanjing Hospital of Traditional Chinese Medicine, a structured approach using the PDCA cycle and PDPC method shows how hospitals can turn renovation from a risk into an opportunity.

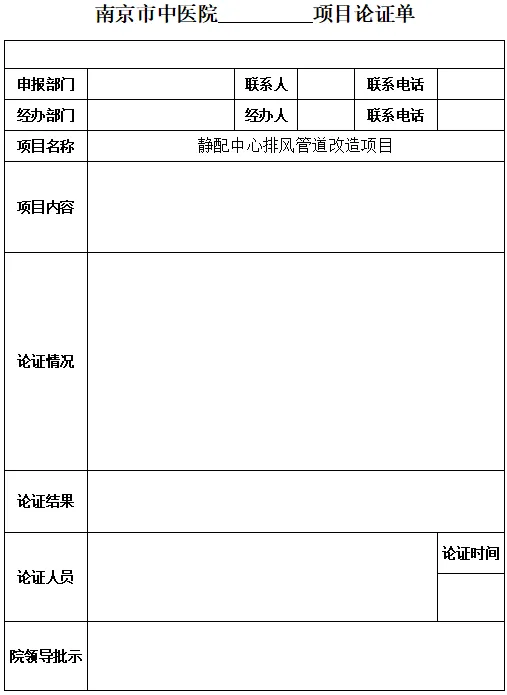

A Structured Pre-Construction Review

The review process builds on the hospital's existing renovation workflow, enhanced by the PDCA cycle and the Process Decision Program Chart (PDPC). This integrated approach anticipates risks early — identifying potential challenges, mapping construction impacts, and developing contingency solutions before work begins.

Putting the Review Mechanism into Practice

Clinic renovations are among the most common — and most complex — hospital projects. They typically involve upgrading plumbing, electrical, heating, ventilation, and interior design systems. At Nanjing Hospital, the process begins with a structured review form, assuming all external construction conditions are in place.

Plan Phase: Defining Three Priorities

1.Clinical Priority – Departments submit requests, followed by on-site surveys to identify functional needs such as additional power outlets for diagnostic equipment or optimized layouts to improve patient flow. These requirements are compiled into a detailed renovation checklist.

2.Process Priority – A joint survey involving General Affairs, Clinical Departments, Infrastructure, and Infection Control teams maps out cross-department coordination, such as water and electricity connections.

3.Safety First – Security, fire, and infection control experts conduct risk assessments to safeguard evacuation routes and sterile areas. For instance, all fencing materials must be fire-resistant to meet hospital safety standards.

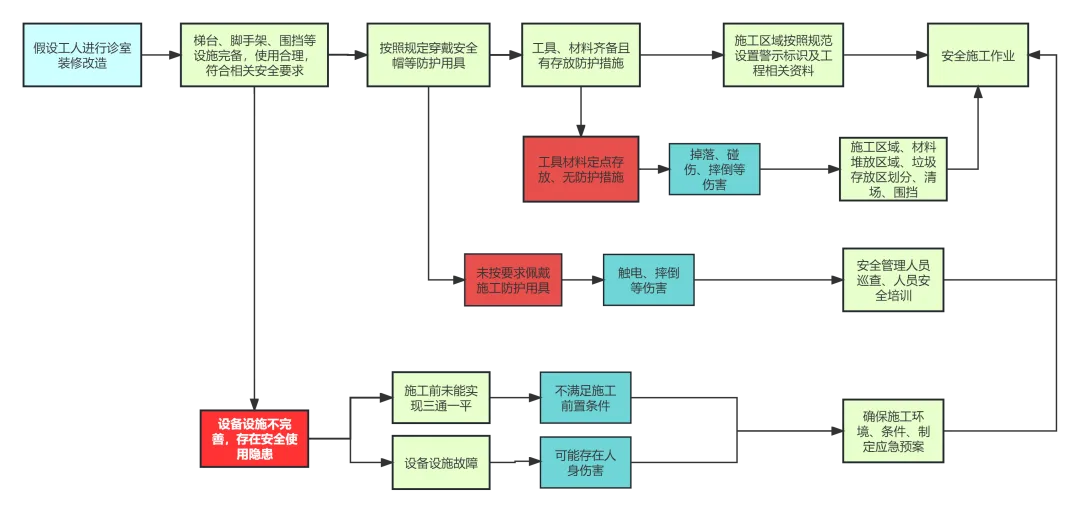

Do Phase: Simulating Risks with the PDPC Method

Once the scope of renovation is defined, the hospital team simulates the construction process under actual site conditions. Using a simplified Process Decision Program Chart (PDPC), they map out each stage of the project to identify potential difficulties and evaluate feasibility (see Figure 2).

The chart illustrates that each step in the clinic renovation can lead to different outcomes. The ideal path is safe, incident-free construction. However, several alternative paths show varying degrees of risk — from property damage to safety incidents — which must be avoided at all costs.

To achieve safe and efficient results, two principles are critical:

Strict compliance with hospital renovation regulations: Projects must follow national standards for existing hospital buildings and implement clear management systems.

Rigorous pre- and mid-construction checks: Given the sensitive hospital environment, teams must inspect the site, apply protective measures, verify tools and materials, and address any safety hazards before work proceeds.

This structured approach is not limited to clinic renovations. It can also be applied to hospital operations more broadly — from equipment installation to facility upgrades — ensuring that potential risks are anticipated and mitigated. With thorough preparation, hospitals can carry out complex renovations confidently, avoiding costly disruptions or major accidents.

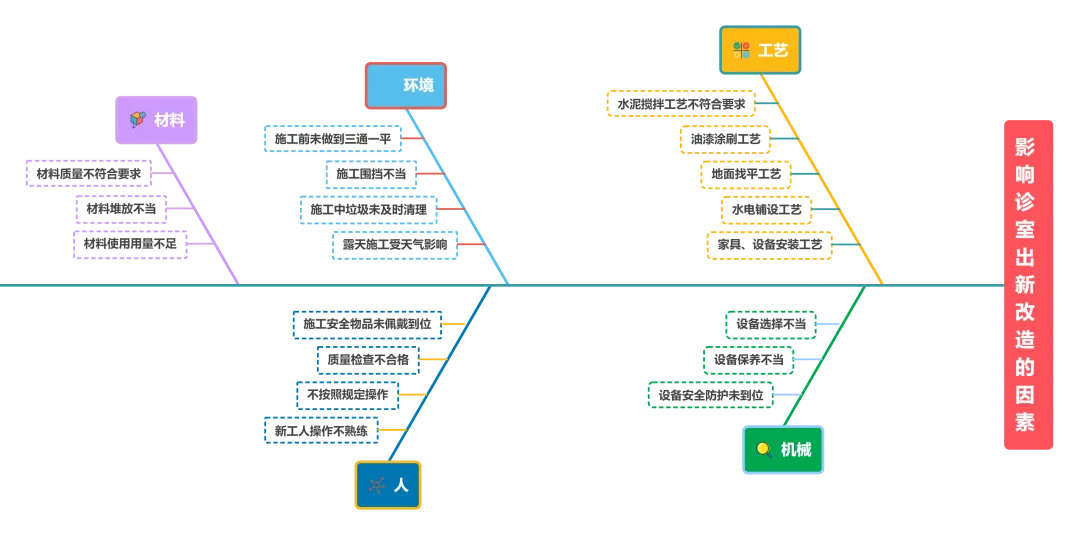

Check Phase: Tracing Quality Issues with Fishbone Analysis

Building on the process decision chart, the team identifies the key factors that influence construction quality and analyzes where problems are most likely to occur. For the clinic renovation project, the management team used a fishbone diagram to examine five critical dimensions: people, machinery, materials, technology, and environment (see Figure 3).

Summary of quality risks:

1. People – Improper operations, lack of responsibility, and weak quality inspections.

2. Machinery – Incorrect use, poor equipment selection, and inadequate maintenance.

3. Materials – Low material quality, insufficient supply, and improper storage.

4. Technology – Plumbing, electrical, flooring, and finishing processes not meeting standards.

5. Environment – Construction site conditions falling short of “three connections and one leveling” requirements, and poor site cleanliness.

To address these risks, the hospital implemented a “look back” mechanism: once a construction step is completed, the team conducts targeted reviews of key processes and quality control points. Any issues are reported and corrected immediately.

Inspection methods include:

Team self-inspections – Construction staff check and correct their own work in critical areas, such as insulation of wire connectors.

Special spot checks – The project leader, together with infection control and audit departments, conducts quality reviews of hidden works (e.g., wall waterproofing) to ensure compliance with hospital acceptance standards.

This systematic inspection process ensures that quality issues are not only identified early but also resolved promptly, strengthening both safety and long-term reliability.

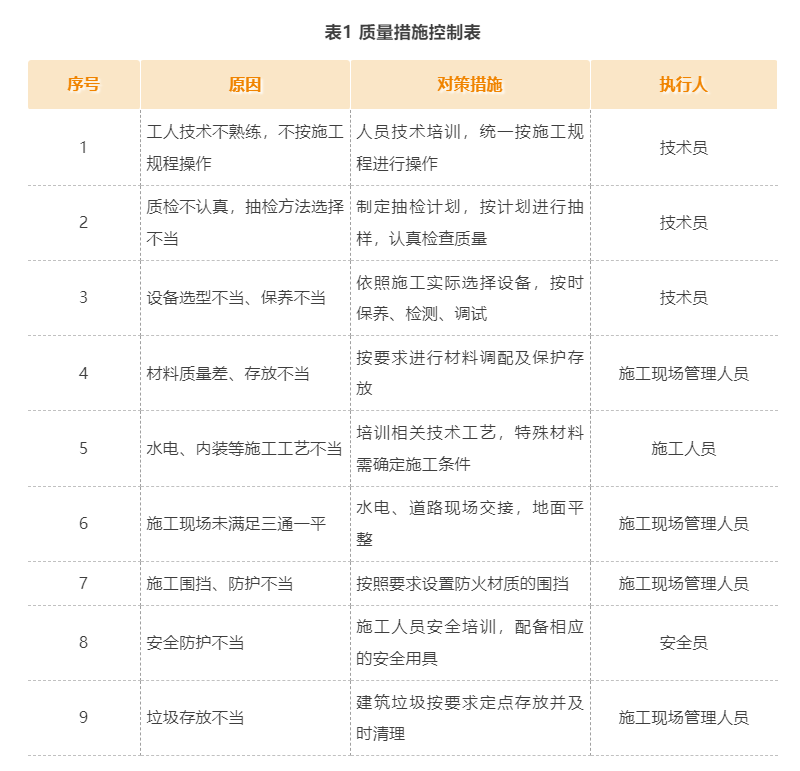

Action (Improvement Phase): Targeted Corrective Measures and Continuous Optimization

For each factor affecting clinic renovation quality (see Figure 3), clear objectives were set and detailed construction plans developed. Measures were implemented across three dimensions — technical quality, efficiency, and service standards — with regular feedback to ensure closed-loop improvement.

Quality Measures Control Table (Table 1) outlined key risks, countermeasures, and responsible parties, covering issues such as worker skills, inspection methods, equipment maintenance, material quality, construction processes, site conditions, safety, and waste management.

Specific Rectification Actions:

Personnel – Technical briefings and training ensured that staff fully understood drawings, workflows, and acceptance procedures. Experts provided on-site guidance for complex areas, while safety and technical training standardized methods and improved compliance.

Environment – The hospital’s engineering liaison coordinated regular site clearance and worked with water, electricity, security, and fire departments to maintain uninterrupted services and safeguard fire protection measures.

Equipment – Appropriate machinery was carefully selected and regularly calibrated. Strict adherence to operational protocols prevented damage, minimized material loss, and ensured worker safety.

Materials & Processes – Long-term supervisors conducted inspections and spot checks throughout the project, with milestone reviews to ensure compliance and consistency in construction quality.

Inspection and Conclusion

After applying the PDCA quality analysis, the feasibility of the minor renovation project was confirmed through assessments of project scope, cost, and schedule. A feasibility report was completed, finalizing the pre-qualification mechanism for small-scale renovations of existing buildings. This process helps reduce foreseeable challenges, enables timely responses to issues, and ensures that lessons learned are documented by technical staff to prevent recurrence in future projects.

Subscribe to our newsletter

Get updated news about CHCC by subscribing CHCC newsletter.

-

Read moreIndustry News 2025.09.04

Read moreIndustry News 2025.09.04China's AI Healthcare Revolution: Smarter, More Efficient Hospitals by 2027

Provinces such as Zhejiang and Hubei are leading the way, integrating AI across clinical care, hospital management, and public health.

-

Read moreIndustry News 2025.09.04

Read moreIndustry News 2025.09.04Creating a Child-Centered Hospital: Lessons from Children's Hospital of Chongqing Medical University

Its approach offers valuable insights for hospital leaders worldwide who are seeking to balance efficiency, patient experience, and family-centered care in pediatric settings.